Recycled Polyester (RPET) Fiber Market Size, Share, Trends, Growth, and Industry Analysis, By Product Type (Fiber, Yarn, Filament), By End-use Industry (Textiles & Apparel, Automotive, Consumer Goods, Packaging, Other Industrial Applications), By Process Type (Mechanical Recycling, Chemical Recycling), By Grade (Standard RPET, High-quality RPET), Regional Analysis and Forecast 2033.

Global Recycled Polyester (RPET) Fiber Market size was USD 16.74 billion in 2024 and the market is projected to touch USD 39.74 billion by 2033, at a CAGR of 11.41% during the forecast period.

RPET fibers are the eco-friendly alternatives to virgin polyester fibers, reducing environmental pollution by recycling plastic waste into valuable textiles. It's often used in the textile industries of apparel, home textiles, and automotive and industrial sectors, providing solutions while maintaining good quality and durability similar to virgin polyester. The market for RPET fibers has been growing steadily with increasing awareness of environmental issues and the demand for sustainable products.

Consumers, especially in the fashion and textile industries, are more inclined towards eco-friendly products, which has spurred growth in the adoption of RPET fibers. In addition, governments around the world are implementing regulations to reduce plastic waste and encourage recycling, which supports the growth of the RPET market. It is further driven by technological advancements in recycling technologies that have made it faster and more cost-effective. In the RPET fiber market, with circular economy principles becoming the focus for sustainability, growth in this area will continue as a business opportunity and industry need to reduce its footprint while delivering products to the consumers that meet green requirements.

Recycled Polyester (RPET) Fiber Report Scope

|

Report Attribute |

Details |

|

Estimated Market Value (2024) |

USD 16.74 Billion |

|

Projected Market Value (2033) |

USD 39.74 Billion |

|

Base Year |

2024 |

|

Historical Year |

2018-2023 |

|

Forecast Years |

2025 – 2033 |

|

Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- Based on By Product Type, By End-use Industry, By Process Type, By Grade, & Region. |

|

Segments Covered |

By Product Type, By End-use Industry, By Process Type, By Grade, & By Region. |

|

Forecast Units |

Value (USD Million or Billion), and Volume (Units) |

|

Quantitative Units |

Revenue in USD million/billion and CAGR from 2025 to 2033. |

|

Regions Covered |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. |

|

Countries Covered |

U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others. |

|

Report Coverage |

Market growth drivers, restraints, opportunities, Porter’s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis. |

|

Delivery Format |

Delivered as an attached PDF and Excel through email, according to the purchase option. |

Dynamic Insights

As awareness over environmental issues has been on the rise, the focus of the consumer and the business has begun to shift more and more toward the use of sustainable materials within products. One such material which has gained more importance in these days is the RPET fibers. The textiles and apparel sector has seen significant use of the same. It further supports a shift toward the circular economy.

Supply-side factors have seen technological advancements in recycling processes. This has meant that the transformation of plastic waste into high-quality fibers has improved efficiency. Therefore, RPET production is made more cost-competitive with virgin polyester fibers. This factor promotes its growth. Governments are enforcing stricter regulations regarding plastic waste management and promoting recycling initiatives. This further boosts the use of RPET fibers. However, some barriers concerning the availability of quality recycled feedstock and the costs of state-of-the art recycling technologies will affect this market growth.

Nevertheless, the ever-growing demand for sustainable textiles, coupled with industry-level efforts to streamline and improve the recycling process, means that the RPET fiber market will continue on an upward trajectory. As companies and consumers look to make a difference on the environment, the use of RPET fibers is expected to grow, therefore becoming a giant in the sustainability movement worldwide.

Drivers Insights

As environmental concerns continue to rise globally, consumers are becoming more conscious of the impact their purchasing decisions have on the planet. This shift in consumer preferences towards sustainability has led to a surge in demand for eco-friendly products, including recycled textiles like RPET fibers. In the fashion and apparel industry, brands are increasingly prioritizing sustainable materials to cater to environmentally aware consumers. As the demand for greener alternatives grows, RPET fibers are being adopted widely due to their eco-friendly nature and similar performance characteristics to virgin polyester, offering brands a sustainable choice without compromising on quality.

Governments worldwide are implementing stricter regulations on plastic waste management and encouraging the adoption of recycling technologies. Policies such as plastic waste bans, extended producer responsibility (EPR) programs, and recycling incentives are driving the growth of the RPET fiber market. For example, the European Union's push to reduce plastic waste and promote circular economies has fostered increased investments in RPET production. These regulatory frameworks not only provide incentives for recycling but also create a favorable environment for businesses involved in the production and use of RPET fibers, further promoting the growth of this market.

Restraints Insights

One of the significant challenges in the RPET fiber market is the availability of high-quality recycled feedstock. While plastic bottles and other PET waste are the primary sources for RPET production, the quality of recycled plastic can vary, affecting the overall quality of the fibers produced. Contamination and inconsistency in the supply of high-grade materials can hinder the production of premium RPET fibers suitable for specific industries, such as fashion or automotive applications. This inconsistency can impact the market's ability to scale and meet growing demand.

While advancements in recycling technologies have made RPET production more efficient, the initial investment required for these technologies remains high. Specialized recycling facilities and equipment are necessary to process PET waste into high-quality RPET fibers. These capital expenditures can be a barrier for smaller companies or new entrants, limiting their ability to participate in the market. Furthermore, the operational costs of maintaining advanced recycling facilities may affect the profitability of RPET manufacturers, particularly in regions where labor and energy costs are high.

Opportunities Insights

In addition to the apparel and textile sectors, the automotive industry presents a promising opportunity for RPET fibers. Automakers are increasingly exploring sustainable materials for interior components such as seat covers, floor mats, and headliners. RPET fibers are an attractive option due to their durability, lightweight properties, and recyclability. As the automotive industry seeks to reduce its environmental footprint and comply with stricter regulations, the adoption of RPET fibers in vehicle manufacturing is expected to rise, creating new avenues for market growth.

Segment Analysis

The global RPET fiber market can be divided into the following product type segments: fiber, yarn, and filament. These fibers are each critical to the production of eco-friendly textiles and other products and, more commonly, come in the form of RPET fibers used in applications such as apparel, home textiles, and automotive interior components. These fibers are usually produced from recycled PET bottles and plastic waste.

Fiber is a product type segment in the global RPET fiber market. RPET yarns are essentially spun fibers used to create woven fabrics, thus contributing to the growing market of sustainable textiles. For most of the fashion fraternity, yarns produced from RPET fibers form the best commodity as they are durable and textured just like virgin polyester, but without any significant harm to the environment. RPET filaments are continuous strands of fiber that are used in a variety of applications, such as industrial textiles, filtration, and more.

The RPET fiber market serves several key end-use industries, including textiles and apparel, automotive, consumer goods, packaging, and other sectors. In the textiles and apparel industry, RPET fibers are widely used to produce sustainable clothing, accessories, and home textiles, as both consumers and companies are increasingly prioritizing eco-friendly products. In the automotive sector, RPET fibers are used for manufacturing interior components like seat covers, floor mats, and headliners, helping automakers reduce their environmental impact while meeting regulatory requirements. RPET fibers also find applications in consumer goods, where they are used in the production of items such as bags, footwear, and other accessories. The packaging industry is another significant user of RPET fibers, especially for creating sustainable and recyclable packaging solutions.

The RPET fiber market is categorized into two main process types: mechanical recycling and chemical recycling. Mechanical recycling involves the physical processing of PET waste, such as plastic bottles, by shredding, melting, and re-spinning the material into fibers, yarns, or filaments. This process is relatively cost-effective but may decrease the quality of the recycled material after multiple recycling cycles. The most widely used process for manufacturing RPET fibers is mechanical recycling. This method is the most commonly applied within industries with standardized quality requirements.

However, chemical recycling is considered more advanced since PET plastic is first broken down into its monomers and then polymerized again to create RPET fibers of a high quality. This route also ensures good quality control as the fibers may come with the same properties as virgin polyester. On the other hand, chemical recycling is costly and requires the development of new technologies. While improvements in recycling technology are on the way, it is envisioned that both types of recycling will significantly contribute to RPET fiber production. Chemical recycling is seen as a means to solve quality problems while mechanical recycling would be needed to ensure massive-scale production.

Based on grade, the RPET fiber market is divided into standard RPET and high-quality RPET. Standard RPET fibers are mostly obtained from recycled PET bottles and other types of plastic waste. These fibers are acceptable in most applications where the highest quality is not necessary, including basic textiles and non-premium consumer goods production. Standard RPET fibers are popular for packaging applications, thermal insulation, and low-cost textile manufacturing.

High purity RPET is then produced through some advanced recycling technologies, which guarantees higher purity levels and consistency as compared to the ordinary recycling processes. Such fibers will be suitable in applications where good performance and long life are involved, such as in the garment, automotive, and premium home textile markets.

High-quality RPET fibers have characteristics close to those of virgin polyester and are hence acceptable for use by high-fashion houses and environmentalist consumers, who want environmentally-friendly yet of quality products. Industries that desire a reduction in environmental impact, for instance, both grades of RPET fibers, are highly driven by growing demand, but superior performance requirements tend to make a case for the use of high-quality RPET.

Regional Analysis

The market is booming in North America due to advances in recycling technology and increasing public awareness of issues related to environmental degradation. Particularly, the major contributor is the United States because key players, such as textiles, automotive industries, and companies in the packaging sector, incorporate RPET fibers to meet not only consumer demands but also stringent regulations. The rising demand for circular economy practices and increase in demand for plastic waste reduction enhance the increase in demand of RPET in this region.

Some other factors such as well-established recycling infrastructure and high investments in technology development increase the growth of the market. The RPET fiber market in Europe is also booming. Here, the growth has been majorly due to strong environmental regulations that the European Union has enforced upon its members by reducing plastic waste and encouraging recycling. Countries such as Germany, France, and the UK have been leading in the adoption of RPET fibers into different industries like automotive, apparel, and packaging.

The Circular Economy Action Plan by the EU aims to enhance plastic recycling rates and reduce reliance on virgin materials, which plays a key role in encouraging a shift toward sustainable fibers. RPET fiber markets in Asia-Pacific are growing at a rapid rate because of the massive production and consumption of recycled plastic materials, particularly in China and India. However, in some parts of the region, challenges such as limited recycling infrastructure and quality control still exist.

Competitive Landscape

The key market players in this industry are large textile companies, recycling firms, and manufacturers of RPET fibers who are concentrating on technological advancement and product innovation for maintaining competitive positions. The other major companies such as Indorama Ventures, Teijin Limited, Unifi, Inc., and SABIC are some of the biggest contributors to the global RPET supply chain. These companies not only invest in advanced recycling technologies but also increase their production capacity to meet the growing demand of RPET fibers in various industries, such as fashion, automotive, and packaging. They also focus more on acquiring certifications and implementing circular economy practices to make their products unique in the market.

The other important aspect of the competitive landscape is the growing emphasis on partnerships and collaborations. Companies are working closely with governments, NGOs, and other organizations to drive sustainability initiatives and create a more robust recycling ecosystem. Smaller, regional players are also emerging, particularly in Asia-Pacific and Latin America, where recycling infrastructure is being developed and demand for sustainable textiles is growing rapidly.

The competition in the market is increasing because players are looking to enhance the quality of RPET fibers, reduce production costs, and increase scale. Moreover, companies are also focusing on brand positioning, as consumers increasingly look for environmentally responsible options, which compels businesses to offer more sustainable and transparent products. As the RPET fiber market develops, competition will likely be aggressive, both technologically and based on changing consumer preferences towards sustainability.

List of Key Players:

Recycled Polyester (RPET) Fiber Report Segmentation

|

ATTRIBUTE |

DETAILS |

|

By Product Type |

|

|

By End-use Industry |

|

|

By Process Type |

|

|

By Grade |

|

|

By Geography |

|

|

Customization Scope |

|

|

Pricing |

|

Research Methodology

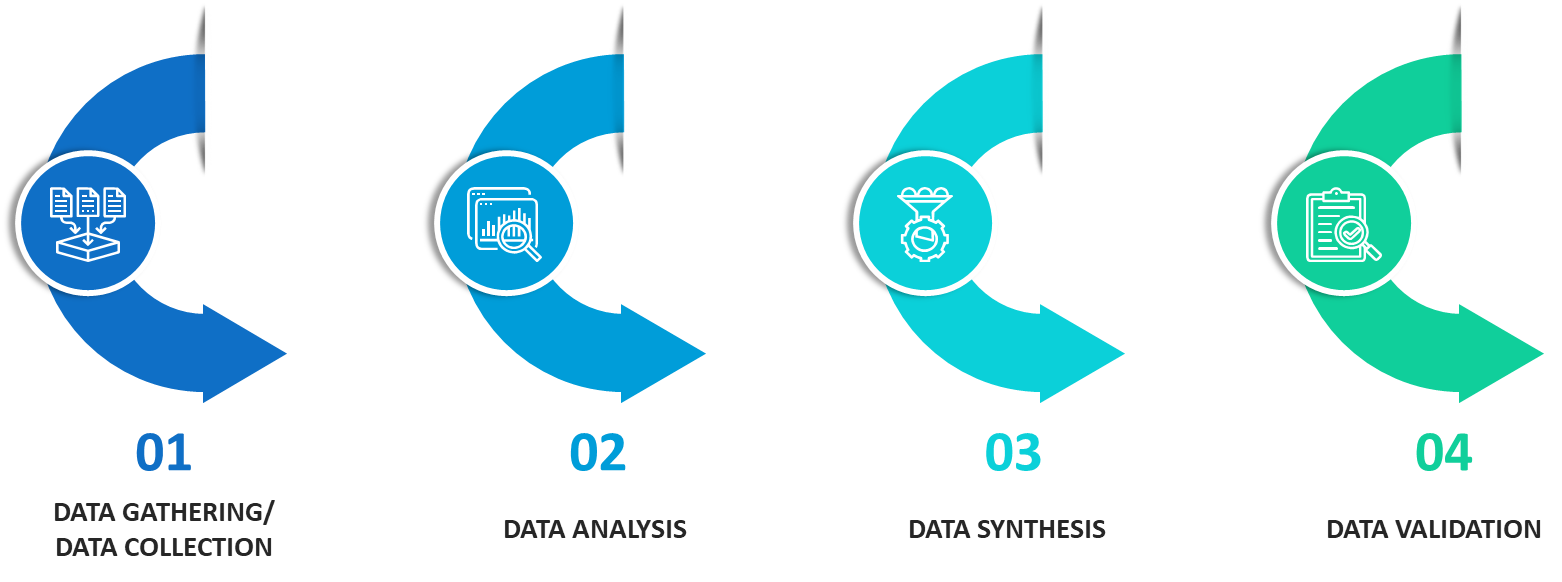

Our research methodology has always been the key differentiating reason which sets us apart in comparison from the competing organizations in the industry. Our organization believes in consistency along with quality and establishing a new level with every new report we generate; our methods are acclaimed and the data/information inside the report is coveted. Our research methodology involves a combination of primary and secondary research methods. Data procurement is one of the most extensive stages in our research process. Our organization helps in assisting the clients to find the opportunities by examining the market across the globe coupled with providing economic statistics for each and every region. The reports generated and published are based on primary & secondary research. In secondary research, we gather data for global Market through white papers, case studies, blogs, reference customers, news, articles, press releases, white papers, and research studies. We also have our paid data applications which includes hoovers, Bloomberg business week, Avention, and others.

Data Collection

Data collection is the process of gathering, measuring, and analyzing accurate and relevant data from a variety of sources to analyze market and forecast trends. Raw market data is obtained on a broad front. Data is continuously extracted and filtered to ensure only validated and authenticated sources are considered. Data is mined from a varied host of sources including secondary and primary sources.

Primary Research

After the secondary research process, we initiate the primary research phase in which we interact with companies operating within the market space. We interact with related industries to understand the factors that can drive or hamper a market. Exhaustive primary interviews are conducted. Various sources from both the supply and demand sides are interviewed to obtain qualitative and quantitative information for a report which includes suppliers, product providers, domain experts, CEOs, vice presidents, marketing & sales directors, Type & innovation directors, and related key executives from various key companies to ensure a holistic and unbiased picture of the market.

Secondary Research

A secondary research process is conducted to identify and collect information useful for the extensive, technical, market-oriented, and comprehensive study of the market. Secondary sources include published market studies, competitive information, white papers, analyst reports, government agencies, industry and trade associations, media sources, chambers of commerce, newsletters, trade publications, magazines, Bloomberg BusinessWeek, Factiva, D&B, annual reports, company house documents, investor presentations, articles, journals, blogs, and SEC filings of companies, newspapers, and so on. We have assigned weights to these parameters and quantified their market impacts using the weighted average analysis to derive the expected market growth rate.

Top-Down Approach & Bottom-Up Approach

In the top – down approach, the Global Batteries for Solar Energy Storage Market was further divided into various segments on the basis of the percentage share of each segment. This approach helped in arriving at the market size of each segment globally. The segments market size was further broken down in the regional market size of each segment and sub-segments. The sub-segments were further broken down to country level market. The market size arrived using this approach was then crosschecked with the market size arrived by using bottom-up approach.

In the bottom-up approach, we arrived at the country market size by identifying the revenues and market shares of the key market players. The country market sizes then were added up to arrive at regional market size of the decorated apparel, which eventually added up to arrive at global market size.

This is one of the most reliable methods as the information is directly obtained from the key players in the market and is based on the primary interviews from the key opinion leaders associated with the firms considered in the research. Furthermore, the data obtained from the company sources and the primary respondents was validated through secondary sources including government publications and Bloomberg.

Market Analysis & size Estimation

Post the data mining stage, we gather our findings and analyze them, filtering out relevant insights. These are evaluated across research teams and industry experts. All this data is collected and evaluated by our analysts. The key players in the industry or markets are identified through extensive primary and secondary research. All percentage share splits, and breakdowns have been determined using secondary sources and verified through primary sources. The market size, in terms of value and volume, is determined through primary and secondary research processes, and forecasting models including the time series model, econometric model, judgmental forecasting model, the Delphi method, among Flywheel Energy Storage. Gathered information for market analysis, competitive landscape, growth trends, product development, and pricing trends is fed into the model and analyzed simultaneously.

Quality Checking & Final Review

The analysis done by the research team is further reviewed to check for the accuracy of the data provided to ensure the clients’ requirements. This approach provides essential checks and balances which facilitate the production of quality data. This Type of revision was done in two phases for the authenticity of the data and negligible errors in the report. After quality checking, the report is reviewed to look after the presentation, Type and to recheck if all the requirements of the clients were addressed.