Printing Ink Additives Market Size, Share, Trends, Growth, and Industry Analysis, By Type (Foam Control Additives, and Rheology Modifiers), By Process (Digital, and Flexography), By Application (Commercial Printing, and Packaging) Regional Analysis and Forecast 2032.

Global Printing Ink Additives market is predicted to reach approximately USD 4.62 billion by 2032, at a CAGR of 6.51% from 2024 to 2032.

Printing Ink Additives are typically blended into the ink formulation to achieve specific characteristics such as improved adhesion, color stability, drying time, and print quality. Key additives include dispersants, rheology modifiers, defoamers, and surface tension modifiers. The market is driven by the growing demand for high-quality printed materials across various industries including packaging, publishing, and advertising. Additionally, advancements in printing technologies and the increasing adoption of digital printing methods are further fuelling the demand for printing ink additives. However, factors such as stringent environmental regulations regarding the use of certain additives and fluctuations in raw material prices pose challenges to market growth.

Global Printing Ink Additives report scope and segmentation.

|

Report Attribute |

Details |

|

Estimated Market Value (2023) |

USD 2.62 Billion |

|

Projected Market Value (2032) |

USD 4.62 Billion |

|

Base Year |

2023 |

|

Forecast Years |

2024 – 2032 |

|

Scope of the Report |

Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- Based on By Type, By Process, By Application, & Region. |

|

Segments Covered |

By Type, By Process, By Application, & By Region. |

|

Forecast Units |

Value (USD Million or Billion), and Volume (Units) |

|

Quantitative Units |

Revenue in USD Million/billion and CAGR from 2024 to 2032. |

|

Regions Covered |

North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. |

|

Countries Covered |

U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others. |

|

Report Coverage |

Market growth drivers, restraints, opportunities, Porter’s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis. |

|

Delivery Format |

Delivered as an attached PDF and Excel through email, according to the purchase option. |

Global Printing Ink Additives dynamics

The growing need for high-quality, bespoke printing solutions across a range of industries, including publishing, textiles, and packaging, is one of the main drivers. Printing ink additive demand is also being driven by consumers' growing preference for digital printing techniques, which call for specific ink formulations. Furthermore, new developments in additive formulations are being sparked by technology breakthroughs in printing materials and methods, which will enhance functionality and performance.

The market is confronted with obstacles, nevertheless, including strict environmental laws that limit the use of specific chemicals, especially those that include volatile organic compounds (VOCs). Manufacturers may have to pay extra to produce environmentally friendly additive solutions in order to comply with these rules. Furthermore, industry participants find it difficult to maintain profit margins and pricing competitiveness due to variable raw material prices.

Furthermore, market dynamics are influenced by competitive factors such as mergers and acquisitions, partnerships, and strategic collaborations among key players. These activities aim to expand market presence, enhance product portfolios, and capitalize on emerging opportunities in niche segments.

Global Printing Ink Additives drivers

The printing business is seeing an increase in demand from a variety of industries, including publishing, advertising, and packaging, for high-quality, bespoke printed goods. The need for sophisticated printing ink additives that can improve print quality, color stability, and overall performance is being driven by this expanding need. The need for specialty additives like colorants and dispersants is predicted to increase dramatically as companies work to produce printed goods that are both aesthetically pleasing and long-lasting in order to draw in customers.

The market for printing ink additives is being driven by the increased adoption of digital printing techniques, which is being fuelled by technological improvements and shifting consumer tastes. Shorter turnaround times, cost-effectiveness for small print runs, and effective customization of prints are just a few benefits of digital printing. Additives that can maximize ink performance for digital printing processes are becoming more and more necessary as the use of digital printing spreads throughout sectors including textiles, labels, and packaging. This will guarantee better print quality, adhesion, and durability.

Restraints:

Stricter environmental rules that aim to reduce the usage of hazardous chemicals and volatile organic compounds (VOCs) are posing difficulties to the printing ink additives business. Manufacturers must make research and development investments in order to create environmentally friendly additives that satisfy regulatory requirements without sacrificing functionality in order to comply with these regulations. Furthermore, switching to greener additives might result in increased production costs, which might have an effect on market participants' profit margins and pricing policies.

The market for additives for printing ink is prone to variations in the cost of raw materials, especially those derived from petrochemicals, like pigments, solvents, and resins. Price volatility for raw materials can have a significant impact on manufacturers' profit margins and production costs, making it difficult for them to maintain competitive pricing. Furthermore, abrupt price changes may cause supply chains to break down and cause problems with inventory management for end users as well as manufacturers.

Opportunities:

The evolving needs of the printing industry present opportunities for manufacturers to innovate and develop new printing ink additives with enhanced performance and functionality. By investing in research and development, companies can create additives that offer superior properties such as improved adhesion, faster drying times, and enhanced color vibrancy, catering to the diverse requirements of end-users across different printing applications.

Segment Overview

The market offers a range of printing ink additives, including foam control additives and rheology modifiers. Foam control additives help in preventing or minimizing foam formation during the ink manufacturing process and printing operations, ensuring smooth and consistent ink application. Rheology modifiers play a crucial role in adjusting the viscosity and flow behaviour of printing inks, enabling precise control over ink consistency and performance. These additives are essential for achieving desired print quality, adhesion, and durability across different printing applications.

Printers employ different printing processes such as digital and flexography, each with distinct characteristics and requirements. Digital printing, characterized by its high-speed, variable data capabilities, and minimal setup requirements, is increasingly preferred for short print runs and personalized printing applications. Flexography, on the other hand, is a versatile and cost-effective printing process commonly used for packaging materials, labels, and corrugated board. Both processes demand tailored printing ink formulations optimized for their specific requirements, driving the demand for process-specific additives that can enhance ink performance and compatibility.

The printing ink additives find extensive application in commercial printing and packaging sectors. Commercial printing encompasses a wide range of printed materials such as brochures, catalogs, magazines, and promotional materials, where print quality, color accuracy, and consistency are paramount. Packaging, including food packaging, cosmetics, pharmaceuticals, and consumer goods packaging, requires specialized inks with properties such as adhesion, flexibility, and resistance to abrasion and chemicals. Additives tailored for commercial printing and packaging applications address specific challenges and requirements, ensuring optimal ink performance and end-product quality.

Global Printing Ink Additives Overview by Region

North America holds a significant share in the market, driven by the presence of major printing ink manufacturers, technological advancements, and a thriving packaging industry. The region's stringent regulatory standards regarding environmental sustainability also contribute to the demand for eco-friendly printing ink additives. In Europe, the market is influenced by similar factors, with a strong emphasis on sustainability and innovation driving the adoption of advanced printing ink additives. Additionally, the region's robust packaging industry, particularly in countries like Germany and the UK, fuels demand for additives catering to diverse packaging applications.

Asia-Pacific emerges as a lucrative market, fuelled by rapid industrialization, urbanization, and expanding commercial printing and packaging sectors. Countries like China, India, and Japan are witnessing substantial investments in printing infrastructure and technologies, driving the demand for printing ink additives. Moreover, the region's burgeoning e-commerce industry and increasing consumer demand for packaged goods further bolster market growth. Latin America and the Middle East & Africa regions also present growth opportunities, albeit to a lesser extent, driven by improving economic conditions, increasing disposable incomes, and rising investments in printing and packaging industries. However, challenges such as volatile raw material prices, regulatory complexities, and geopolitical uncertainties may hinder market growth in these regions.

Global Printing Ink Additives market competitive landscape

Leading companies such as BASF SE, Evonik Industries AG, and Dow Chemical Company dominate the market with their extensive product portfolios and strong distribution networks. These companies focus on developing advanced printing ink additives that cater to diverse customer requirements, including improved print quality, durability, and sustainability. Moreover, strategic collaborations and partnerships with raw material suppliers, technology providers, and end-users enable these companies to enhance their product offerings and expand their market presence globally. Additionally, mergers and acquisitions play a significant role in shaping the competitive landscape, with companies seeking to strengthen their market positions, access new markets, and leverage synergies to drive growth. Emerging players such as Clariant AG, DIC Corporation, and Elementis PLC are also making significant investments in research and development to introduce innovative additives and gain a competitive edge in the market. Furthermore, increasing focus on sustainable solutions and environmental regulations is prompting companies to develop eco-friendly printing ink additives, thereby enhancing their competitiveness and meeting evolving customer demand.

Global Printing Ink Additives Recent Developments

Scope of global Printing Ink Additives report

Global Printing Ink Additives report segmentation

|

ATTRIBUTE |

DETAILS |

|

By Type |

|

|

By Process |

|

|

By Application |

|

|

By Geography |

|

|

Customization Scope |

|

|

Pricing |

|

Objectives of the Study

The objectives of the study are summarized in 5 stages. They are as mentioned below:

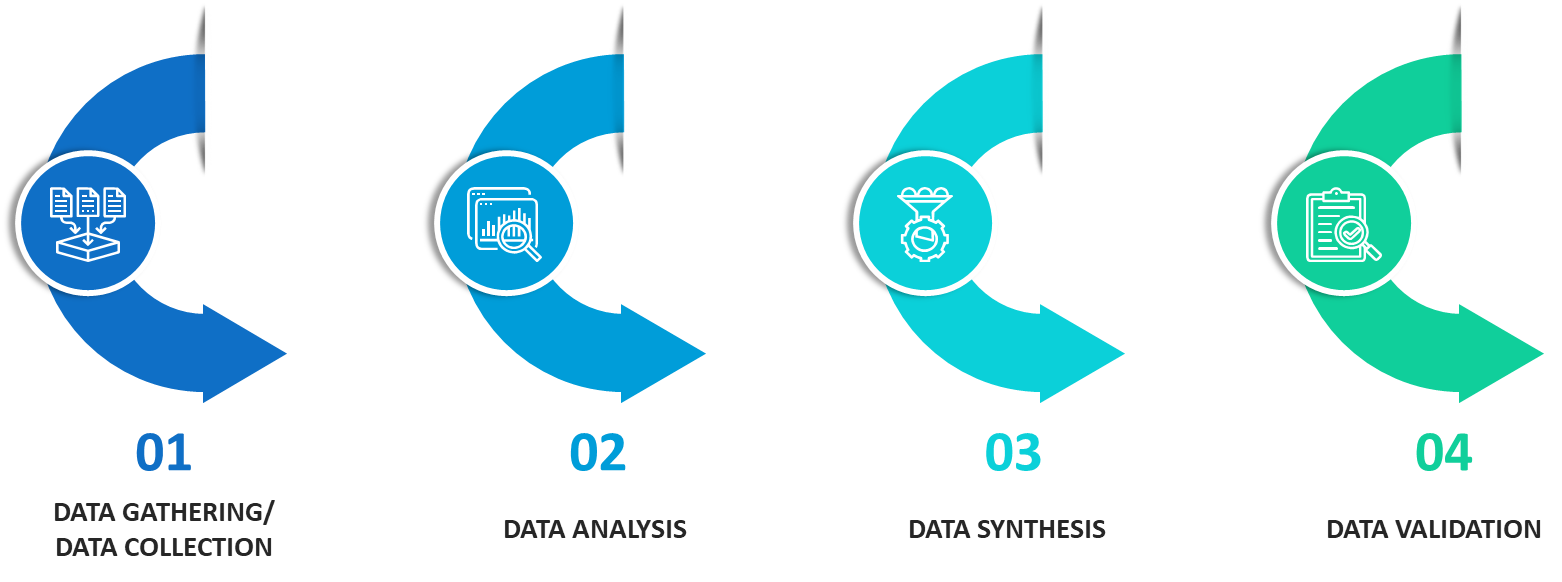

Research Methodology

Our research methodology has always been the key differentiating reason which sets us apart in comparison from the competing organizations in the industry. Our organization believes in consistency along with quality and establishing a new level with every new report we generate; our methods are acclaimed and the data/information inside the report is coveted. Our research methodology involves a combination of primary and secondary research methods. Data procurement is one of the most extensive stages in our research process. Our organization helps in assisting the clients to find the opportunities by examining the market across the globe coupled with providing economic statistics for each and every region. The reports generated and published are based on primary & secondary research. In secondary research, we gather data for global Market through white papers, case studies, blogs, reference customers, news, articles, press releases, white papers, and research studies. We also have our paid data applications which includes hoovers, Bloomberg business week, Avention, and others.

Data Collection

Data collection is the process of gathering, measuring, and analyzing accurate and relevant data from a variety of sources to analyze market and forecast trends. Raw market data is obtained on a broad front. Data is continuously extracted and filtered to ensure only validated and authenticated sources are considered. Data is mined from a varied host of sources including secondary and primary sources.

Primary Research

After the secondary research process, we initiate the primary research phase in which we interact with companies operating within the market space. We interact with related industries to understand the factors that can drive or hamper a market. Exhaustive primary interviews are conducted. Various sources from both the supply and demand sides are interviewed to obtain qualitative and quantitative information for a report which includes suppliers, product providers, domain experts, CEOs, vice presidents, marketing & sales directors, Type & innovation directors, and related key executives from various key companies to ensure a holistic and unbiased picture of the market.

Secondary Research

A secondary research process is conducted to identify and collect information useful for the extensive, technical, market-oriented, and comprehensive study of the market. Secondary sources include published market studies, competitive information, white papers, analyst reports, government agencies, industry and trade associations, media sources, chambers of commerce, newsletters, trade publications, magazines, Bloomberg BusinessWeek, Factiva, D&B, annual reports, company house documents, investor presentations, articles, journals, blogs, and SEC filings of companies, newspapers, and so on. We have assigned weights to these parameters and quantified their market impacts using the weighted average analysis to derive the expected market growth rate.

Top-Down Approach & Bottom-Up Approach

In the top – down approach, the Global Batteries for Solar Energy Storage Market was further divided into various segments on the basis of the percentage share of each segment. This approach helped in arriving at the market size of each segment globally. The segments market size was further broken down in the regional market size of each segment and sub-segments. The sub-segments were further broken down to country level market. The market size arrived using this approach was then crosschecked with the market size arrived by using bottom-up approach.

In the bottom-up approach, we arrived at the country market size by identifying the revenues and market shares of the key market players. The country market sizes then were added up to arrive at regional market size of the decorated apparel, which eventually added up to arrive at global market size.

This is one of the most reliable methods as the information is directly obtained from the key players in the market and is based on the primary interviews from the key opinion leaders associated with the firms considered in the research. Furthermore, the data obtained from the company sources and the primary respondents was validated through secondary sources including government publications and Bloomberg.

Market Analysis & size Estimation

Post the data mining stage, we gather our findings and analyze them, filtering out relevant insights. These are evaluated across research teams and industry experts. All this data is collected and evaluated by our analysts. The key players in the industry or markets are identified through extensive primary and secondary research. All percentage share splits, and breakdowns have been determined using secondary sources and verified through primary sources. The market size, in terms of value and volume, is determined through primary and secondary research processes, and forecasting models including the time series model, econometric model, judgmental forecasting model, the Delphi method, among Flywheel Energy Storage. Gathered information for market analysis, competitive landscape, growth trends, product development, and pricing trends is fed into the model and analyzed simultaneously.

Quality Checking & Final Review

The analysis done by the research team is further reviewed to check for the accuracy of the data provided to ensure the clients’ requirements. This approach provides essential checks and balances which facilitate the production of quality data. This Type of revision was done in two phases for the authenticity of the data and negligible errors in the report. After quality checking, the report is reviewed to look after the presentation, Type and to recheck if all the requirements of the clients were addressed.