Polyurethane Foam Market

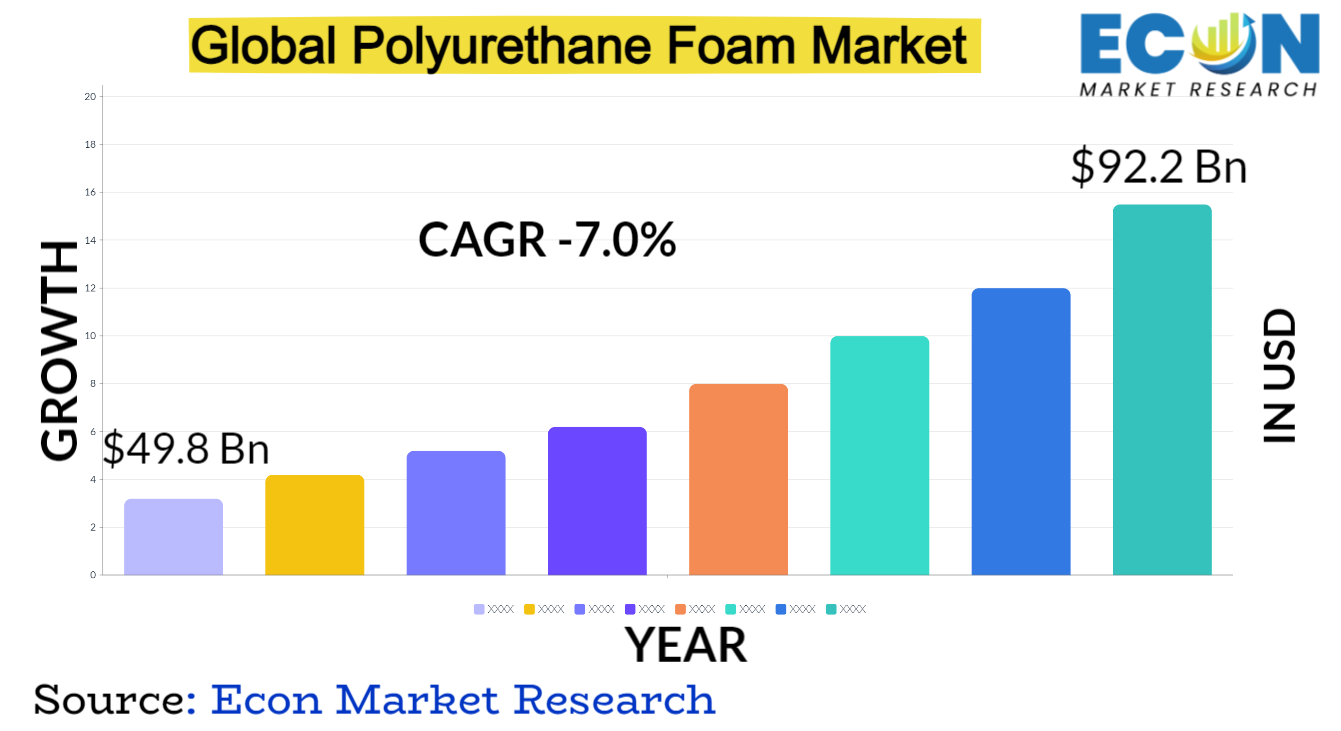

The Polyurethane Foam Market was valued at USD 49.8 billion in 2023 and is estimated to reach approximately USD 92.2 billion by 2032, at a CAGR of 7.0% from 2024 to 2032.

Since its introduction, the market for polyurethane foam has grown significantly. Since its invention in the middle of the 20th century, polyurethane foam has transformed a number of industries thanks to its adaptability, toughness, and light weight. Its versatility led to its extensive adoption in the construction, automotive, packaging, and fu iture sectors after it was first utilized in cushioning and insulation applications. Because of this foam',s outstanding insulating qualities, which promote energy efficiency in appliances and buildings, its popularity has skyrocketed. It became a mainstay in the fu iture industry due to its usage in durable and comfy fu iture cushioning.

Its lightweight design helped the vehicle industry by increasing fuel efficiency without sacrificing comfort or safety. As demand increased, producers responded with creativity, developing a variety of formulas to meet distinct requirements. Its use range was subsequently broadened with the development of environmentally friendly and fire-retardant versions. The market saw a trend toward sustainable formulations as a result of ongoing technological breakthroughs and increased environmental conce s, solidifying its position as an essential material for a variety of industries. Even with sporadic issues with disposal and environmental impact, the polyurethane foam sector is still growing. Its flexibility and continuous R&,D guarantee its relevance across a range of industries, fostering innovation and sustainability in the global marketplace.

POLYURETHANE FOAM MARKET: REPORT SCOPE &, SEGMENTATION

| Report Attribute | Details |

| Estimated Market Value (2023) | 49.8 Bn |

| Projected Market Value (2032) | 92.2 Bn |

| Base Year | 2023 |

| Forecast Years | 2024 - 2032 |

| Scope of the Report | Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- By Product, By Density Composition, By End-User, &, Region |

| Segments Covered | By Product, By Density Composition, By End-User, &, Region |

| Forecast Units | Value (USD Billion or Million), and Volume (Units) |

| Quantitative Units | Revenue in USD million/billion and CAGR from 2024 to 2032 |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, and Middle East &, Africa, and the Rest of World |

| Countries Covered | U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others |

| Report Coverage | Market growth drivers, restraints, opportunities, Porter&rsquo,s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis, and COVID-19 impact analysis. |

| Delivery Format | Delivered as an attached PDF and Excel through email, according to the purchase option. |

Polyurethane Foam Market Dynamics

Numerous dynamic factors impact the polyurethane foam industry, shaping its growth and development. A variety of factors are included in market dynamics, such as variations in supply and demand, advances in technology, alterations in laws, and changes in customer tastes. The growing infrastructure and building industries are a major market driver. Because of its exceptional insulating qualities, polyurethane foam is a vital component of contemporary architecture, encouraging ecological and energy-efficient building methods.

The market is expanding as a result of the car industry',s need for lightweight materials to improve fuel efficiency, since polyurethane foam satisfies these needs without sacrificing comfort or safety. Market dynamics do, however, provide certain difficulties. The industry is impacted by environmental conce s about the disposal of foam and the source of raw materials. Manufacturing procedures and product formulas are impacted by regulatory changes intended to lower emissions and promote sustainable practices. Developments in technology have a significant impact on how markets are shaped.

Foam formulation innovations that use recycled or bio-based content address the growing consumer demand for environmentally friendly products. Research and development efforts to improve the performance and versatility of foam are also being driven by changing consumer preferences for more robust and pleasant goods. Because of the way these dynamic factors interact, the polyurethane foam market is always changing. Industry participants must adjust to shifts in regulations, technology, sustainability, and customer demands while maintaining environmental responsibility.

Polyurethane Foam Market Drivers

- Construction and Infrastructure Development

Because of its remarkable insulating qualities and adaptability, this foam is a crucial component of contemporary building techniques. The building industry is moving toward more sustainable and energy-efficient building solutions, and polyurethane foam is becoming an essential component. Its capacity to reduce heat loss through excellent thermal insulation in walls, roofs, and foundations improves a building',s overall energy efficiency. Its lightweight design also makes installation simpler and cuts down on labor expenses and construction time.

The need for polyurethane foam is further increased by the growing emphasis on green construction standards and laws throughout the world. Architects and builders look for materials that might help them ea certifications like LEED and that satisfy strict energy requirements. Due to its ability to maximize temperature management and form airtight seals, polyurethane foam is becoming increasingly popular in both residential and commercial construction projects. These sustainability aims are ideally aligned with the material',s capabilities. The need for effective insulation solutions is a result of growing infrastructure needs and urbanization, which reinforces polyurethane foam',s position as a major player in the building and infrastructure industries.

- Consumer Goods and Fu iture Industry

,Because of its adaptability, toughness, and comfort, polyurethane foam is a key component in this industry. It provides consumers with a balance between support and comfort in couches, mattresses, chairs, and other home items that are manufactured with it. Long-lasting, cozy fu iture is made possible by the foam',s capacity to take on different forms while maintaining its resilience. Products that provide comfort and durability without sacrificing sustainability are becoming more and more important to consumers. In response, producers of polyurethane foam have created bio-based foams, incorporated recycled content, or innovated environmentally friendly formulas to satisfy consumer needs. Its lightweight design also makes it simpler to handle during production, which lowers costs associated with the making of fu iture. Within the consumer goods industry, polyurethane foam is used in packaging, footwear, and recreational equipment in addition to fu iture. Because of its cushioning qualities, it is perfect for protective packing that ensures fragile objects are transported safely.

Restraints:

- Environmental Conce s and Regulations

Because polyurethane foam is not biodegradable and may release hazardous chemicals during production, its manufacture and disposal pose environmental risks. Stricter laws that seek to reduce emissions and encourage sustainable practices in a range of businesses have been prompted by this. Manufacturers', operating expenses will rise as a result of the investments required to comply with these standards in environmentally friendly production methods and formulations. Furthermore, there is a growing need for more sustainable substitutes as a result of customers', increased knowledge of how the things they purchase affect the environment.

Consumer preferences are shifting toward more environmentally friendly solutions, which puts pressure on conventional polyurethane foam manufacturing techniques and necessitates innovation in biodegradability and recycling. The non-biodegradable nature of polyurethane foam makes end-of-life management difficult, which raises issues with trash accumulation and pollution of the environment. Disposal is another problem. Foam recycling and repurposing efforts are fraught with technical difficulties and demand expenditures in specialized recycling infrastructure.

- End-of-Life Disposal Challenges

Because polyurethane foam doesn',t break down easily, disposing of it poses a serious environmental risk. Conventional landfill disposal exacerbates land use problems and environmental damage by allowing non-biodegradable garbage to continue to accumulate. Bu ing polyurethane foam could produce toxic fumes that are bad for the environment and human health. Recycling is a workable approach, but it has drawbacks. Effective recycling techniques are hampered by the complicated composition of polyurethane foam as well as the presence of impurities and additives. Although mechanical recycling is possible in certain situations, it frequently results in materials that are of worse quality and have fewer uses. While chemical recycling and novel technologies hold great potential, they will need substantial expenditures and breakthroughs to reach large-scale efficiency. Widespread foam recycling activities are further hampered by the absence of standardized recycling procedures and established infrastructure. Therefore, the practical choices for handling polyurethane foam waste in an environmentally responsible manner are limited by the scarcity of recycling facilities.

Opportunities:

- Rising Demand for Energy-Efficient Solutions

Improving the energy efficiency of buildings, appliances, and transportation systems is becoming more and more important as awareness of sustainability and energy conservation spreads throughout the world. Because of its outstanding insulating qualities, polyurethane foam is a great option for meeting these requirements. Its capacity to provide excellent thermal insulation and airtight seals makes a substantial contribution to increased energy efficiency. By minimizing heat transfer during construction, polyurethane foam insulation lessens the need for excessive heating or cooling of structures. This reduces energy use and complies with strict energy regulations and green building certifications.

The insulation properties of polyurethane foam also help appliances and refrigeration systems, increasing their energy efficiency and lowering overall power consumption. This foam is used by the automobile industry to lighten vehicles, improving fuel economy by doing so without sacrificing performance or safety. The need of polyurethane foam in accomplishing emissions reduction and energy saving is growing as global regulatory organizations push for these goals.

- Innovation in Sustainable Formulations

As environmental effect is becoming more widely recognized, businesses and consumers are looking for more environmentally friendly options. Manufacturers of polyurethane foam now have a great chance to invest in R&,D, with an emphasis on sustainable formulations, thanks to this shift in demand. Creating polyurethane foams with recycled or bio-based components is in line with consumer demand for greener products. Bio-based foams provide a more environmentally friendly option to their petroleum-based counterparts by lowering dependency on finite fossil fuel supplies. They are made from renewable resources such as plant oils or agricultural byproducts. Incorporating recycled materials into the foam production process also promotes a circular economy model and reduces waste. Moreover, the development of environmentally friendly foams with performance metrics that are on par with conventional versions is made possible by improvements in chemical compositions and production techniques. These technologies satisfy changing consumer preferences for long-lasting, high-quality products in addition to sustainability goals.

Segment Overview

- By Product

Based on product, the global polyurethane foam market is divided into rigid foam, flexible foam, and spray foam. The spray foam category dominates the market with the largest revenue share in 2023. Polyurethane spray foam is a versatile material applied using specialized equipment, expanding upon application to create a tight seal and insulation. It comes in two primary types: open-cell and closed-cell. Open-cell spray foam is softer and allows for moisture vapor transmission, while closed-cell spray foam is denser and provides a stronger insulation barrier.

Spray foam finds applications in insulation for buildings, sealing gaps and cracks, and in roofing for its insulation and waterproofing properties. Rigid polyurethane foam is known for its structural strength, thermal insulation properties, and high density. It',s commonly used in construction and insulation applications, such as insulating walls, roofs, and refrigeration units. Rigid foam provides excellent thermal resistance, making it an ideal choice for buildings requiring high energy efficiency and temperature control. Flexible polyurethane foam is characterized by its softness, cushioning properties, and flexibility. This type of foam is extensively used in fu iture, bedding, automotive seating, and packaging. Its ability to conform to various shapes while providing comfort and support makes it a popular choice in these applications.

- By Density Composition

Based on the density composition, the global polyurethane foam market is categorized into low-density composition, medium-density composition, and high-density composition. The medium-density composition category leads the global polyurethane foam market with the largest revenue share in 2023. Medium-density polyurethane foam falls within the range of 2 to 4 pounds per cubic foot (32 to 64 kilograms per cubic meter). This foam type strikes a balance between firmness and flexibility. It finds applications in fu iture, automotive seating, sound insulation, and some construction uses where both support and comfort are necessary. Medium-density foam offers good durability and support while retaining some level of softness.

Low-density polyurethane foam typically ranges from about 1 to 2 pounds per cubic foot (16 to 32 kilograms per cubic meter). This type of foam is lightweight, soft, and flexible. It',s often used in applications where cushioning and comfort are essential, such as in mattresses, pillows, upholstery, and packaging materials. Low-density foam provides excellent cushioning and conformability, making it suitable for comfort-based products. High-density polyurethane foam is typically above 4 pounds per cubic foot (64 kilograms per cubic meter). It is dense, strong, and rigid, offering excellent structural support, durability, and insulation properties. High-density foam is commonly used in construction for insulation purposes, as well as in structural elements where strength and load-bearing capabilities are crucial.

- By End-User

Based on end-user, the global polyurethane foam market is segmented into building &, construction, bedding &, fu iture, automotive, footwear, electronics, packaging, and others. The automotive segment dominates the polyurethane foam market.In the automotive sector, polyurethane foam is utilized in car seats, headrests, armrests, interior panels, and sound insulation. Its lightweight nature contributes to fuel efficiency while offering comfort and durability in vehicle interiors. Polyurethane foam is extensively used in mattresses, pillows, sofas, chairs, and various fu iture components. Its cushioning properties provide comfort and support, making it a popular choice in the bedding and fu iture industry.

Polyurethane foam is employed in shoe soles, providing cushioning, shock absorption, and support. It enhances comfort and performance in various types of footwear, from athletic shoes to casual wear. Within electronics, polyurethane foam is used for packaging delicate components, providing cushioning and protection during transportation. It shields sensitive electronics from impact and vibration damage. Polyurethane foam',s shock-absorbing properties make it ideal for protecting fragile items during shipping and handling. It',s used in packaging applications across various industries, safeguarding products from damage.

Polyurethane Foam Market Overview by Region

The global polyurethane foam market is categorized into North America, Europe, Asia-Pacific, and the Rest of the World. Asia-Pacific emerged as the leading region, capturing the largest market share in 2023. Polyurethane foam is in high demand across a wide range of industries due to rapid industrialization, urbanization, and strong economic development in nations like China, India, Japan, South Korea, and Southeast Asia. Polyurethane foam is being used much more frequently in the construction industry as insulation because of the region',s emphasis on building energy-efficient structures and developing infrastructure.

Additionally, the growing automotive sector in nations like China and India has increased demand for foam in the production of automobiles, especially for interior and seating components because of its lightweight nature and capacity to improve comfort. With polyurethane foam being widely used in mattresses, fu iture, and other consumer products, the expanding consumer goods and fu iture markets in the area have also been contributing causes. Innovation in polyurethane foam formulations has been further stimulated by the region',s manufacturing expertise and the trend toward sustainable and eco-friendly materials, which is in line with the growing demand for more environmentally friendly options. All things considered, the Asia-Pacific region',s rising consumer markets, varied industrial landscape, and developing infrastructure have helped it maintain its position as the world',s largest market for polyurethane foam.

Polyurethane Foam Market Competitive Landscape

In the global polyurethane foam market, a few major players exert significant market dominance and have established a strong regional presence. These leading companies remain committed to continuous research and development endeavors and actively engage in strategic growth initiatives, including product development, launches, joint ventures, and partnerships. By pursuing these strategies, these companies aim to strengthen their market position, expand their customer base, and capture a substantial share of the market.

Some of the prominent players in the global polyurethane foam market include Huntsman Corporation, The Dow Chemical Company, BASF SE, Sekisui Chemical Co., Ltd., Trelleborg AG, Future Foam, Inc., Elliott Co. of Indianapolis, Inc., Recticel S.A., Foamcraft, Inc., UFP Technologies, Inc., Rogers Corporation, Wanhua Chemical Group Co., Ltd., Saint-Gobain S.A., and various other key players.

Polyurethane Foam Market Recent Developments

- In June 2023, One of the most well-known producers of foam-based goods, Sheela Foam, intended to invest USD 395.51 million to purchase Kurlon Enterprise. As Sheela Foam grows its product line and market presence, this strategic move is a big step forward for the company. Sheela Foam obtains access to a robust brand, a wide distribution network, and a varied customer base with the acquisition of Kurlon Enterprise.

Polyurethane Foam Market Report Segmentation

| ATTRIBUTE | , , , , ,DETAILS |

| By Product |

|

| By Density Composition |

|

| By End-User |

|

| By Geography |

|

| Customization Scope |

|

| Pricing |

|

,

Report Details

- Published Date2024-12-22T15:59:46

- FormatPDF

- LanguageEnglish