Aseptic Packaging Market

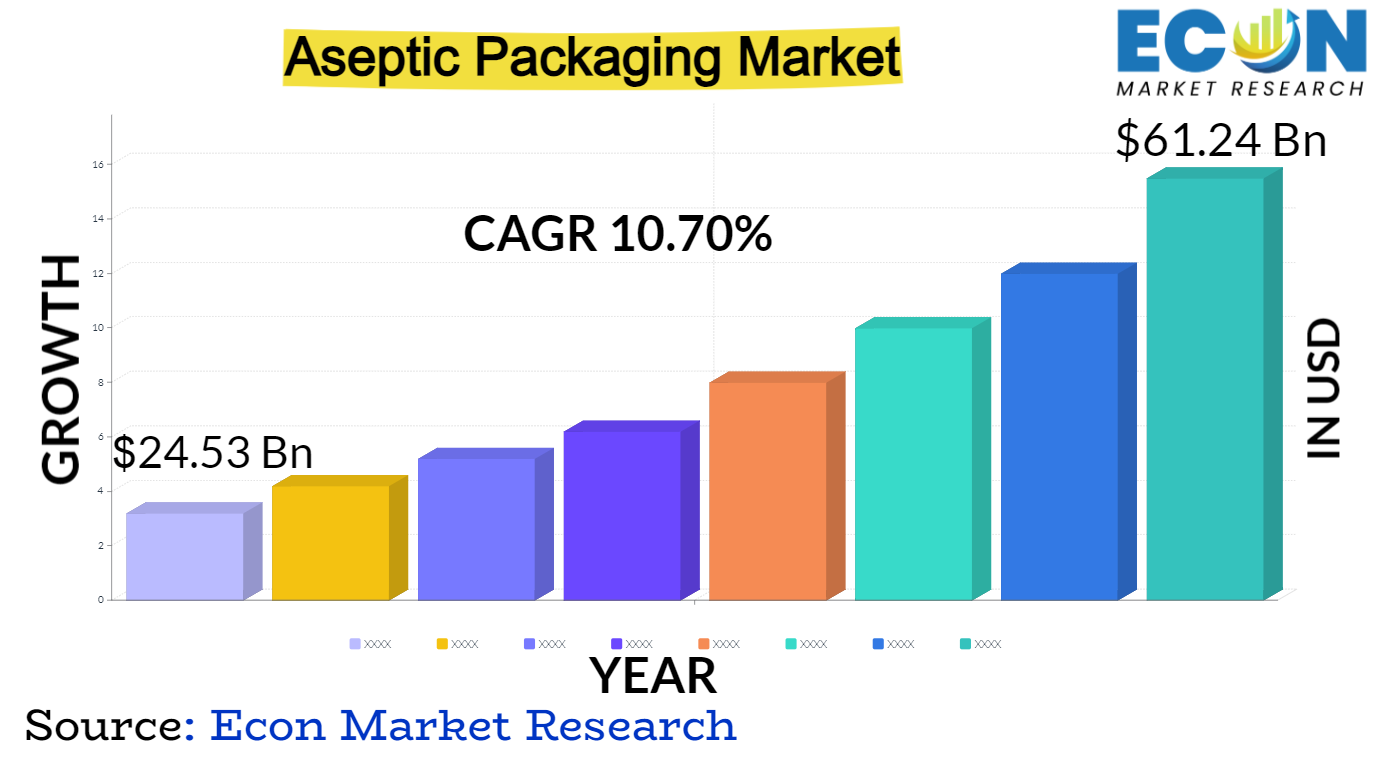

Global Aseptic Packaging market is predicted to reach approximately USD 61.24 billion by 2032, at a CAGR of 10.70% from 2024 to 2032.

Aseptic packaging refers to the method of filling sterile products into sterile containers in a sterile environment to maintain their shelf life without refrigeration or chemical preservatives. The global aseptic packaging market is experiencing significant growth attributed to the increasing demand for convenient and safe packaging solutions across various industries such as food and beverage, pharmaceuticals, and healthcare.

The market is driven by factors such as the growing preference for convenient and ready-to-eat food products, rising conce s regarding food safety and hygiene, and advancements in packaging technology. Moreover, the expanding urban population, changing lifestyle patte s, and increasing disposable incomes further contribute to the market',s expansion. Aseptic packaging offers several advantages including prolonged shelf life, reduced transportation costs, enhanced product safety, and improved storage efficiency, thereby driving its adoption across diverse sectors. However, challenges such as high initial investment costs and stringent regulatory requirements may hinder market growth to some extent.

Despite these challenges, manufacturers are increasingly focusing on developing innovative and sustainable packaging solutions to cater to evolving consumer preferences and regulatory standards. Geographically, the Asia-Pacific region is expected to witness substantial growth in the aseptic packaging market owing to rapid urbanization, industrialization, and increasing consumer awareness regarding food safety and hygiene. Additionally, strategic initiatives such as mergers and acquisitions, collaborations, and product innovations are prevalent among key players to strengthen their market presence and gain a competitive edge.

Aseptic Packaging Report Scope and Segmentation

| Report Attribute | Details |

| Estimated Market Value (2023) | USD 24.53 billion |

| Projected Market Value (2032) | USD 61.24 billion |

| Base Year | 2023 |

| Forecast Years | 2024 &ndash, 2032 |

| Scope of the Report | Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- Based on By Product, By Application, &, Region. |

| Segments Covered | By Product, By Application, &, By Region. |

| Forecast Units | Value (USD Billion or Million), and Volume (Units) |

| Quantitative Units | Revenue in USD million/billion and CAGR from 2024 to 2032. |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, and Middle East &, Africa. |

| Countries Covered | U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others. |

| Report Coverage | Market growth drivers, restraints, opportunities, Porter&rsquo,s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis. |

| Delivery Format | Delivered as an attached PDF and Excel through email, according to the purchase option. |

Aseptic Packaging Dynamics

The growing need for practical and secure packaging options in a variety of sectors, including food and beverage, pharmaceutical, and healthcare, is one important motivator. As a result of consumers', growing preferences for ready-to-eat and portable food items, aseptic packaging&mdash,which extends shelf life without requiring refrigeration or preservatives&mdash,is in high demand. Additionally, aseptic packaging solutions have become more popular due to growing conce s about food safety and hygiene, as they help prevent contamination and preserve product integrity throughout the supply chain.

Technological developments in packaging are another important factor propelling market expansion. In order to develop novel packaging materials and methods that maximise product safety, reduce environmental impact, and increase cost-effectiveness, manufacturers are investing in research and development. As a result of rising packaged food and beverage consumption brought on by changing lifestyle patte s and an expanding urban population, there is an even greater need for aseptic packaging solutions.

Notwithstanding, the market encounters obstacles like elevated initial investment expenses and rigorous regulatory mandates. For manufacturers, creating sterile production environments and guaranteeing adherence to regulatory requirements can be expensive and time-consuming. Further difficulties for market participants come from shifting raw material prices and the requirement for constant innovation to satisfy changing consumer preferences.

Aseptic Packaging Drivers

- Growing Demand for Convenient and Safe Packaging Solutions:

The increasing preference for convenient and safe packaging solutions across various industries, including food and beverage, pharmaceuticals, and healthcare, is a major driver for the aseptic packaging market. Consumers are increasingly seeking ready-to-eat and on-the-go food products, which require packaging that can maintain freshness and safety without the need for refrigeration or preservatives. Aseptic packaging offers extended shelf life and helps prevent contamination, addressing consumers', conce s about food safety and hygiene. Furthermore, as lifestyles become more fast-paced, the demand for convenient packaging solutions continues to rise, driving the adoption of aseptic packaging technologies globally.

- Advancements in Packaging Technology:

The aseptic packaging market is expanding due to technological advancements in the packaging industry. In order to develop new materials, procedures, and tools that increase product safety, lessen their negative effects on the environment, and increase their cost-effectiveness, manufacturers are spending money on research and development. Manufacturers can accomplish greater levels of sterility, accuracy, and efficiency in the packaging process thanks to advanced aseptic packaging technologies.

Furthermore, cutting-edge packaging innovations like clever packaging solutions and eco-friendly packing materials are gaining popularity and providing sustainable substitutes for conventional packaging techniques. In addition to satisfying consumer expectations for environmentally friendly and safe packaging, these technological developments also help manufacturers increase their operational efficiency and competitiveness.

Restraints:

One of the significant restraints for the aseptic packaging market is the high initial investment required for setting up sterile manufacturing environments and acquiring specialized equipment. Establishing aseptic packaging facilities involves substantial capital investment in infrastructure, machinery, and personnel training to ensure compliance with stringent regulatory standards. Additionally, ongoing maintenance and operational costs further contribute to the financial burden on manufacturers, especially for small and medium-sized enterprises (SMEs). The high entry barriers due to capital-intensive nature limit the market entry of new players and pose challenges for existing manufacturers looking to expand their operations.

- Stringent Regulatory Requirements:

The aseptic packaging industry is subject to stringent regulatory requirements imposed by gove ment authorities and inte ational standards organizations to ensure product safety and quality. Compliance with regulations such as Good Manufacturing Practices (GMP), Hazard Analysis and Critical Control Points (HACCP), and Food and Drug Administration (FDA) guidelines is essential for manufacturers to operate in the market.

Meeting regulatory standards entails significant investments in quality control measures, documentation, and audits, which can increase operational costs and complexity. Moreover, frequent updates and changes in regulatory requirements pose challenges for manufacturers in maintaining compliance and adapting to evolving standards, thereby restraining market growth.

Opportunities:

- Focus on Sustainable Packaging Solutions:

Growing environmental conce s and heightened awareness of sustainability are creating opportunities for the aseptic packaging market. Consumers are increasingly seeking eco-friendly packaging alte atives that minimize environmental impact and support recycling and waste reduction efforts. Aseptic packaging technologies offer several advantages in terms of resource efficiency, energy savings, and recyclability compared to traditional packaging materials such as glass and metal.

Manufacturers can leverage this growing demand for sustainable packaging solutions by investing in eco-friendly materials, optimizing packaging designs, and promoting recycling initiatives. Moreover, gove ments and regulatory bodies are implementing policies and incentives to encourage the adoption of sustainable packaging practices, further driving market growth.

Segment Overview

- By Product

By product, the aseptic packaging market encompasses a variety of packaging types tailored to different consumer needs and industry requirements. Cartons, including popular brands like Tetra Pak and Combibloc, represent a significant segment within aseptic packaging. These cartons offer lightweight, durable, and customizable packaging solutions suitable for a wide range of products, including beverages, dairy, and processed foods. Bags and pouches are another prominent product segment, known for their flexibility, portability, and convenience. These packaging formats are commonly used for packaging liquids, snacks, and other consumables, offering consumers on-the-go convenience and portion control.

Cans and bottles, although traditional packaging formats, continue to be widely used in the aseptic packaging market, particularly for beverages and pharmaceutical products. Cans provide excellent protection against light and oxygen, making them suitable for preserving the quality and freshness of beverages, while bottles offer versatility in shape, size, and material, catering to diverse packaging needs across industries.

- By Application

In terms of applications, the aseptic packaging market serves various sectors, with beverages emerging as a primary application segment. Ready-to-drink beverages, including juices, teas, and sports drinks, are commonly packaged using aseptic technology to ensure product safety and extend shelf life. Dairy-based beverages, such as milk and yogurt drinks, also rely on aseptic packaging to maintain freshness and nutritional quality without the need for refrigeration. The food application segment encompasses a wide range of products, including processed foods, fruits, vegetables, and dairy products.

Aseptic packaging helps preserve the flavor, texture, and nutritional value of these food items while offering convenience and extended shelf life. In the pharmaceutical sector, aseptic packaging plays a critical role in preserving the efficacy and safety of drugs and medical products. Sterile packaging solutions ensure product integrity and compliance with regulatory standards, making aseptic packaging indispensable for pharmaceutical companies worldwide.

Aseptic Packaging Overview by Region

North America holds a prominent position in the market, driven by the robust demand for convenient and safe packaging solutions across the food and beverage, pharmaceutical, and healthcare industries. The region benefits from a well-established infrastructure, advanced manufacturing capabilities, and stringent regulatory standards, which encourage the adoption of aseptic packaging technologies. Moreover, changing consumer lifestyles, increasing disposable incomes, and growing conce s regarding food safety and hygiene contribute to the market',s growth in North America.

Similarly, Europe emerges as a key market for aseptic packaging, propelled by the region',s strong emphasis on sustainability, innovation, and quality assurance. European consumers prioritize eco-friendly packaging solutions and are receptive to novel packaging formats and materials that enhance product safety and environmental sustainability. Additionally, stringent regulations gove ing food and pharmaceutical packaging drive the adoption of aseptic packaging technologies across the European market. In the Asia-Pacific region, rapid urbanization, expanding middle-class population, and rising consumer awareness fuel the demand for aseptic packaging solutions.

Countries such as China, India, and Japan witness significant market growth attributed to increasing consumption of packaged foods, beverages, and pharmaceutical products. Moreover, gove ment initiatives promoting food safety, hygiene, and technological innovation further bolster market expansion in the Asia-Pacific region. Latin America and the Middle East &, Africa regions also present lucrative opportunities for the aseptic packaging market, driven by urbanization, industrialization, and changing consumer preferences. While these regions face challenges related to infrastructure development, economic instability, and regulatory complexities, they offer untapped potential for market players willing to invest in localized production facilities and strategic partnerships.

Aseptic Packaging Market Competitive Landscape

Key players such as Tetra Pak, SIG Combibloc Group AG, Amcor Limited, and Elopak AS dominate the market with their extensive product portfolios, global reach, and strong brand recognition. These industry leaders continually invest in research and development to introduce advanced packaging solutions that address evolving consumer preferences, regulatory requirements, and sustainability conce s. Moreover, strategic collaborations, mergers, and acquisitions are prevalent strategies among major players to enhance their market presence, expand geographical footprint, and diversify product offerings. Additionally, companies are focusing on developing eco-friendly packaging materials, reducing carbon footprint, and improving operational efficiencies to stay competitive in the market.

Alongside established players, a growing number of startups and niche players are entering the aseptic packaging market, leveraging innovative technologies and business models to disrupt traditional packaging practices. These emerging companies focus on niche markets, specialty applications, and customized packaging solutions to cater to specific industry needs and consumer demands. Furthermore, technological advancements such as smart packaging, active and intelligent packaging, and digital printing are reshaping the competitive landscape, offering new opportunities for differentiation and value creation. As competition intensifies, companies are investing in marketing initiatives, brand building, and customer engagement strategies to differentiate their offerings and build long-term relationships with clients.

Aseptic Packaging Market Leading Companies:

-

Amcor Limited

-

Tetra Pak Inte ational S.A.

-

SIG Combibloc Group

-

Sealed Air Corporation

-

Schott AG

-

Robert Bosch GmbH

-

Reynolds Group Holdings Limited

-

Becton, Dickinson and Company

-

Greatview Aseptic Packaging Co. Ltd

-

IPI SRL (Coesia Group)

-

DS Smith PLC

-

UFlex Limited

-

Elopak AS

-

Mondi PLC

-

Smurfit Kappa Group

Aseptic Packaging Recent Developments

- Nov 2023, following a successful commercial consumer testing phase in 2022, Tetra Pak, in collaboration with Lactogal, has recently introduced an aseptic beverage carton incorporating a paper-based barrier. This initiative is part of a comprehensive technology validation endeavor, which includes approximately 25 million packages and is currently underway in Portugal.

- April 2023, SIG is launching SIG Digital Printing for aseptic carton packs manufactured in Europe. This innovative printing solution provides full-color digital printing without the necessity for cylinders or printing forms, offering flexibility and responsiveness to cater to individual customer requirements.

Global Aseptic Packaging Report Segmentation

| ATTRIBUTE | , , , , ,DETAILS |

| By Product |

|

| By Application |

|

| By Geography |

|

| Customization Scope |

|

| Pricing |

|

,

FAQs

Report Details

- Last UpdatedJanuary 31, 2026

- FormatPDF

- LanguageEnglish