Air Density Separator Market

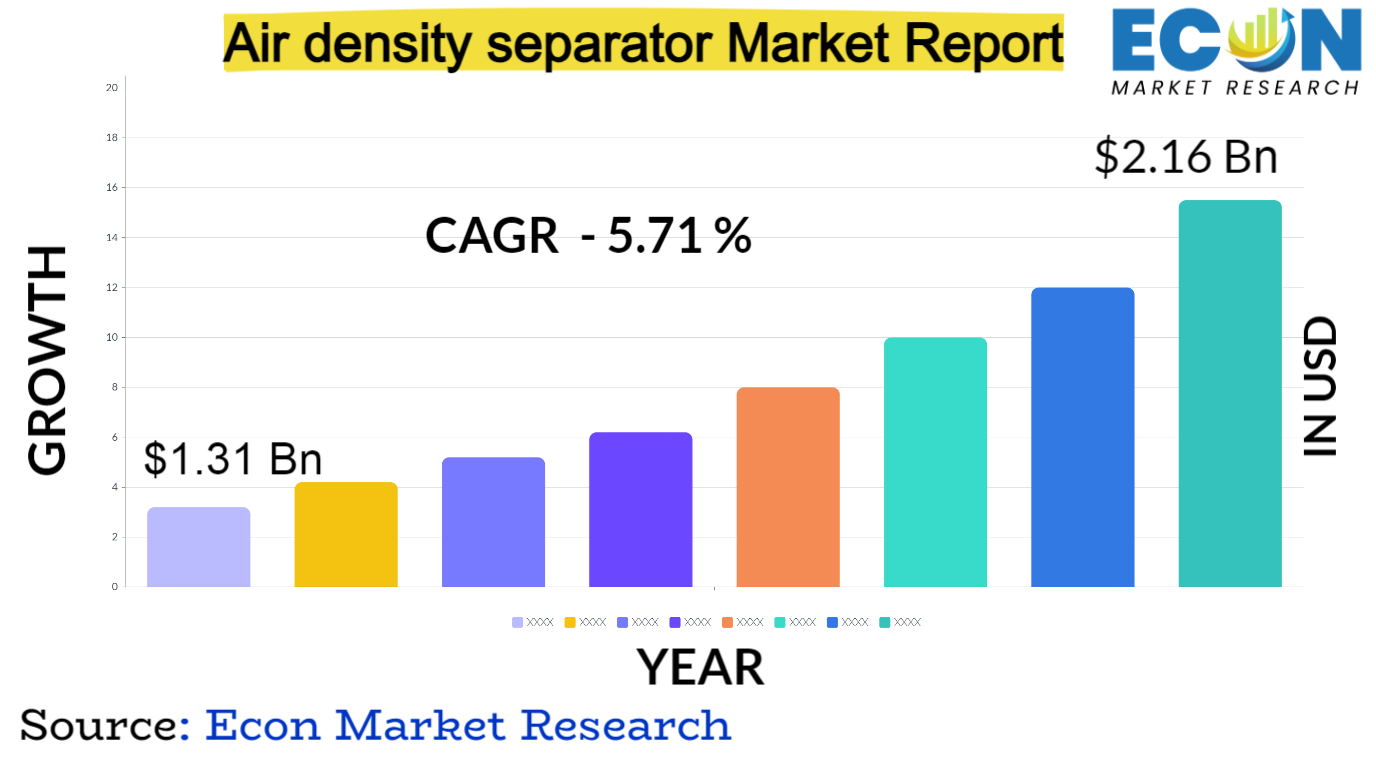

global air density separator market size was USD 1.31 billion in 2023 and the market is projected to touch USD 2.16 million by 2032, at a CAGR of 5.71% during the forecast period.

As a highly effective and eco-friendly solution, an air density separator uses state-of-the-art technology to separate materials according to differences in density. This cutting-edge apparatus works on the basis of using air as a medium to separate and stratify different materials, making it possible to distinguish between lighter and heavier particles. Because of its adaptability, it is essential to a variety of applications, including mining and recycling facilities.

| Report Attribute | Details |

| Estimated Market Value (2023) | USD 1.31 billion |

| Projected Market Value (2032) | USD 2.16 billion |

| Base Year | 2023 |

| Forecast Years | 2024 &ndash, 2032 |

| Scope of the Report | Historical and Forecast Trends, Industry Drivers and Constraints, Historical and Forecast Market Analysis by Segment- Based on By Application &, Region. |

| Segments Covered | By Application &, By Region. |

| Forecast Units | Value (USD Billion or Million), and Volume (Units) |

| Quantitative Units | Revenue in USD million/billion and CAGR from 2024 to 2032. |

| Regions Covered | North America, Europe, Asia Pacific, Latin America, and Middle East &, Africa. |

| Countries Covered | U.S., Canada, Mexico, U.K., Germany, France, Italy, Spain, China, India, Japan, South Korea, Brazil, Argentina, GCC Countries, and South Africa, among others. |

| Report Coverage | Market growth drivers, restraints, opportunities, Porter&rsquo,s five forces analysis, PEST analysis, value chain analysis, regulatory landscape, market attractiveness analysis by segments and region, company market share analysis. |

| Delivery Format | Delivered as an attached PDF and Excel through email, according to the purchase option. |

Air Density Separator Dynamics

With continuous research and development efforts aimed at improving the effectiveness and adaptability of air density separators, technological innovation continues to be a major driver. In order to position the market for long-term growth, manufacturers are investing in state-of-the-art designs that provide increased precision, throughput, and adaptability to a wider range of materials.

As pressure mounts on industries across the globe to adopt sustainable practices, environmental factors become increasingly important in determining market dynamics. The potential of the air density separator to aid in resource recovery and waste reduction is consistent with the increasing emphasis on environmental responsibility worldwide. Air density separator adoption is accelerating across industries, especially in waste management and recycling facilities, as a result of strict regulations designed to reduce carbon footprints and promote circular economies.

Air Density Separator Drivers

- Technological Advancements

The market for air density separators is primarily driven by ongoing technological advancements. The goal of ongoing research and development is to improve these separators', accuracy, efficiency, and versatility. To maximise material separation procedures, manufacturers are investing in cutting-edge designs and sensor technologies, such as machine lea ing and artificial intelligence. These developments increase air density separators', overall performance and increase their versatility, which broadens their range of applications in a variety of industries. The incorporation of intelligent technologies facilitates instantaneous monitoring and regulation, culminating in amplified operational efficacy and mitigated ecological ramifications, thereby propelling the market',s expansion.

- Increasing Environmental Regulations

The escalating stringency of environmental regulations globally is a significant driver for the air density separator market. Gove ments and regulatory bodies are imposing stringent standards to promote sustainable practices and reduce the environmental impact of industrial processes. Air density separators contribute to these goals by facilitating effective waste management and resource recovery. Industries, particularly in waste management and recycling, are compelled to adopt these separators to comply with regulations aimed at minimizing landfill waste and promoting circular economies. The market benefits from a growing awareness among industries about the positive environmental outcomes achieved through the implementation of air density separators, positioning them as essential tools in meeting regulatory requirements.

Restraints:

The high initial cost of purchasing and installing these cutting-edge systems is one of the main factors impeding the market for air density separators. Air density separators have relatively high upfront costs due to their sophisticated technology and materials, which makes them unaffordable for some businesses, especially smaller ones. Due to their capital-intensive nature, these investments may not be widely adopted, especially in areas or sectors of the economy with limited financial resources. To solve this issue and make these technologies more widely available, manufacturers and industry players should look into financially-motivated design solutions and ways to reduce costs.

- Operational Challenges and Maintenance

Air density separators provide effective material separation, but their potential for maintenance problems and operational difficulties can impede the market',s expansion. Because of these systems', complexity and the requirement for regular maintenance to guarantee optimal performance, there may be downtime, which lowers end users', overall productivity. Training programmes and thorough maintenance procedures must be invested in in order to address these operational issues. To mitigate these challenges and ensure consistent and dependable performance for end users, manufacturers and service providers should concentrate on creating user-friendly designs and proactive maintenance strategies.

Opportunities:

- Expanding Applications in Emerging Industries

By reaching out to new markets, the air density separator market offers substantial growth prospects. These separators have increasing potential in industries like construction, recycling of electronic waste, and agriculture, in addition to their conventional uses in waste management and mining. Air density separators can find new uses in industries looking for creative approaches to material separation, which will propel market expansion. Manufacturers can take advantage of these opportunities by expanding the range of products they offer and customising solutions to meet the unique requirements of developing markets.

Segment Overview

- By Application ,

The air density separator market is characterized by diverse applications across various industries. In the realm of recycling and waste processing, these separators are instrumental in sorting materials like plastics and metals, contributing to waste reduction and sustainable practices. The chemical industry leverages air density separators for precise separation of different compounds, enhancing production efficiency and product purity. In the food and beverages sector, these separators play a vital role in quality control by efficiently removing contaminants from food products.

Air density separators are essential in the mining and minerals sector for removing valuable minerals from ore and maximising processing effectiveness. These separators are useful for the agricultural industry in the processing of seeds and sorting of grains, as they guarantee even planting and increase crop yields. Air density separators are particularly useful instruments in these sectors, providing effective material separation solutions to meet the particular requirements of mining, agriculture, food processing, recycling, and chemical processing. Their ability to boost output, advance sustainability, and satisfy sector-specific needs places them in a position to play a significant role in the expansion and effectiveness of many industries on a worldwide basis.

Air Density Separator Overview by Region

In North America, the market is driven by stringent environmental policies, fostering the adoption of air density separators in waste management and recycling operations. The region',s well-established mining and construction industries also contribute to market growth. Air density separator demand is driven by a strong emphasis on sustainability and circular economy practices in Europe, especially in the waste processing and chemical industries. Furthermore, a developed industrial landscape and gove ment initiatives that are supportive improve market penetration.

The Asia-Pacific region exhibits significant market potential due to its swift industrialization and developing economies. Air density separator adoption is fuelled by rising environmental pollution conce s and growing awareness of sustainable practices in nations like China and India. The Asia-Pacific region',s mining and minerals industry contributes significantly to market expansion. The Middle East and Latin America',s developing industrial infrastructures have an impact on the market.

Air Density Separator Market Competitive Landscape

Key market participants such as Hillenbrand, Inc. (U.S.), Acrowood (U.S.), M&,K (U.K.), Blue Group (U.K.), and ANDRITZ dominate the space with their comprehensive product portfolios and extensive geographic reach. These industry leaders focus on continuous technological advancements to enhance the efficiency and capabilities of their air density separators, ensuring they remain at the forefront of market competition. Additionally, strategic collaborations, mergers, and acquisitions are prevalent strategies among major players to strengthen their market position and expand their offerings.

Air Density Separator Market Leading Companies:

,

-

Neuenhauser Group

-

Hillenbrand, Inc.

-

Acrowood

-

Senro

-

TANA

-

ANDRITZ

-

Westeria

-

M&,K

Air Density separator Recent Developments

- Jan 2023, Alfa Laval high-speed separators are presently designed to work seamlessly with biofuel blends, specifically hydrotreated vegetable oil (HVO EN15940) and fatty acid methyl ester (FAME EN14214 or ASTM D6751), when mixed with residual fuel or distillates. ,

Air Density Separator Report Segmentation

| ATTRIBUTE | , , , , ,DETAILS |

| By Application |

|

| By Geography |

|

| Customization Scope |

|

| Pricing |

|

,

Report Details

- Published Date2024-12-22T15:59:46

- FormatPDF

- LanguageEnglish